Heavy-Duty Industrial Floor Mats: The Essential Tool for Workplace Safety and Efficiency

In industrial settings, ensuring the safety and comfort of workers is a top priority. Heavy-duty industrial floor mats play a crucial role in achieving this goal. Whether used in warehouses, factories, assembly lines, or other rugged environments, these mats offer more than just a surface to stand on. They are engineered to provide safety, reduce fatigue, protect floors, and improve overall productivity. This article explores the many benefits of heavy-duty industrial floor mats, their applications, and how they contribute to a safer and more efficient workplace.

What Are Heavy-Duty Industrial Floor Mats?

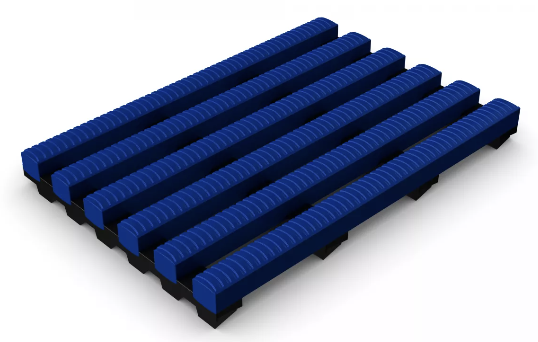

Heavy-duty industrial floor mats are specially designed to withstand harsh conditions commonly found in industrial settings. These mats are constructed from robust materials like rubber, vinyl, and polyurethane, which offer superior durability, resistance to chemicals, oils, and heavy machinery, and can handle substantial weight and traffic.

Available in various types, such as anti-fatigue mats, slip-resistant mats, and drainage mats, each serves a unique purpose to fit specific industrial needs. The ability to endure tough conditions while providing comfort and safety makes these mats indispensable in many industries.

Why Are Heavy-Duty Floor Mats Important?

Worker Safety One of the primary reasons for using heavy duty industrial floor mats is to enhance workplace safety. Slips, trips, and falls are common accidents in industrial environments, and they can lead to serious injuries. Mats with slip-resistant surfaces offer excellent traction, even in wet or oily conditions, reducing the risk of accidents. This safety feature is particularly vital in industries like automotive, manufacturing, and food processing, where spills or leaks are common.

Ergonomic Benefits Many industrial jobs require workers to stand for long hours, which can lead to fatigue, discomfort, and even long-term health issues like joint pain or muscle strain. Anti-fatigue mats are specially designed to reduce the strain on muscles and joints by providing cushioning and support. This type of mat encourages subtle movements, which improves circulation and reduces overall fatigue, allowing workers to remain comfortable and focused for longer periods.

Floor Protection Heavy machinery, equipment, and constant foot traffic can take a toll on industrial floors. Over time, concrete or tile floors can crack, wear down, or become stained from oils and chemicals. Heavy-duty floor mats act as a protective barrier, preventing damage to the flooring and saving on costly repairs or replacements. By absorbing impacts, they also reduce the noise levels caused by machinery or dropped tools, creating a more pleasant work environment.

Hygiene and Cleanliness In industries like food processing, pharmaceuticals, or healthcare, maintaining a clean environment is critical. Industrial mats with drainage features allow liquids, debris, and dust to pass through the mat, keeping the work area dry and clean. This not only reduces the risk of slips but also prevents the spread of contaminants. Mats can be easily cleaned or replaced, ensuring that hygiene standards are upheld without disrupting operations.

Chemical and Fire Resistance Industrial settings often expose mats to chemicals, oils, and sometimes even sparks or fire. High-quality industrial mats are resistant to these hazards, making them suitable for environments where exposure to corrosive materials or high temperatures is a concern. Mats made from nitrile rubber, for example, offer excellent chemical resistance, while others are designed to withstand exposure to flames, making them ideal for welding areas or places with high heat.

Key Applications of Heavy-Duty Industrial Floor Mats

Manufacturing and Assembly Lines In manufacturing plants, workers often spend hours standing or moving along assembly lines. Anti-fatigue mats are commonly used in these areas to provide support and reduce strain on workers’ legs and backs. These mats can also be customized to fit the layout of the assembly line, ensuring that employees are protected across the entire workspace.

Warehouses and Distribution Centers Warehouses require mats that can withstand heavy equipment like forklifts and pallet jacks while providing a safe, slip-resistant surface for workers. Industrial floor mats used in these settings should be durable, easy to clean, and capable of handling heavy traffic. Mats placed in loading dock areas or around high-traffic zones provide a stable surface for workers moving large boxes or machinery.

Automotive and Mechanical Shops In automotive repair shops or mechanical environments, spills from oil, grease, or other fluids are common. Mats that offer oil resistance and drainage capabilities are crucial in these settings to prevent slipping and to maintain a safe, clean workspace. These mats are also designed to resist the weight of heavy vehicles and equipment.

Food Processing Plants Cleanliness and hygiene are paramount in food processing environments. Mats with drainage systems are ideal in wet areas to allow fluids to pass through, keeping the surface dry. These mats also feature anti-microbial properties, preventing the growth of bacteria and fungi, which is essential in food production environments.

Chemical and Pharmaceutical Industries In chemical or pharmaceutical plants, workers are often exposed to hazardous materials. Mats that are resistant to chemicals, acids, and oils provide protection for both the workers and the floors. These mats are engineered to prevent the absorption of harmful substances, making them suitable for laboratories or production areas where chemicals are frequently used.

Choosing the Right Heavy-Duty Floor Mat

When selecting heavy-duty industrial floor mats, several factors should be considered:

- Material: Different industries require different materials. Rubber mats are great for slip resistance, while polyurethane mats are ideal for anti-fatigue purposes. Nitrile rubber mats work well in chemical-resistant environments.

- Size and Thickness: The size and thickness of the mat should match the specific needs of the workspace. Thicker mats provide more cushioning, while larger mats cover more surface area, ensuring complete protection.

- Special Features: Mats with beveled edges reduce the risk of tripping, while mats with drainage holes keep workspaces dry. Anti-microbial mats are also available for industries that prioritize hygiene.

Conclusion

Heavy-duty Direct textile store are an essential tool in maintaining safety, comfort, and efficiency in industrial environments. From reducing slips and falls to minimizing fatigue and protecting floors, these mats provide numerous benefits that directly contribute to worker productivity and well-being. Investing in the right floor mat for your specific industry needs can lead to long-term savings, fewer workplace accidents, and a healthier workforce.

Post Comment